Rigid Multiple Component PUR PU Raw Building Materials Polyurethane Foam Chemical for on and Above 10mm Sandwich Panel

Package Size 60.00cm * 60.00cm * 102.00cm Package Gross Weight 218.000kg BLEND POLYOL LY7105 LY-7105 is a special polyol

Basic Info.

| Model NO. | LY7105 |

| Free Rise Density | 28 Kg/M3 |

| Density (DIN51757) | 1, 15-1, 20 g/cm3 |

| Hydroxy Number (ASTM 4274-05) | 370±20 Mg KOH/G |

| Water Content (ASTM 4672-00) | Max. 2 % |

| Acid Number (DIN 2114) | Max. 1 Mg KOH/G |

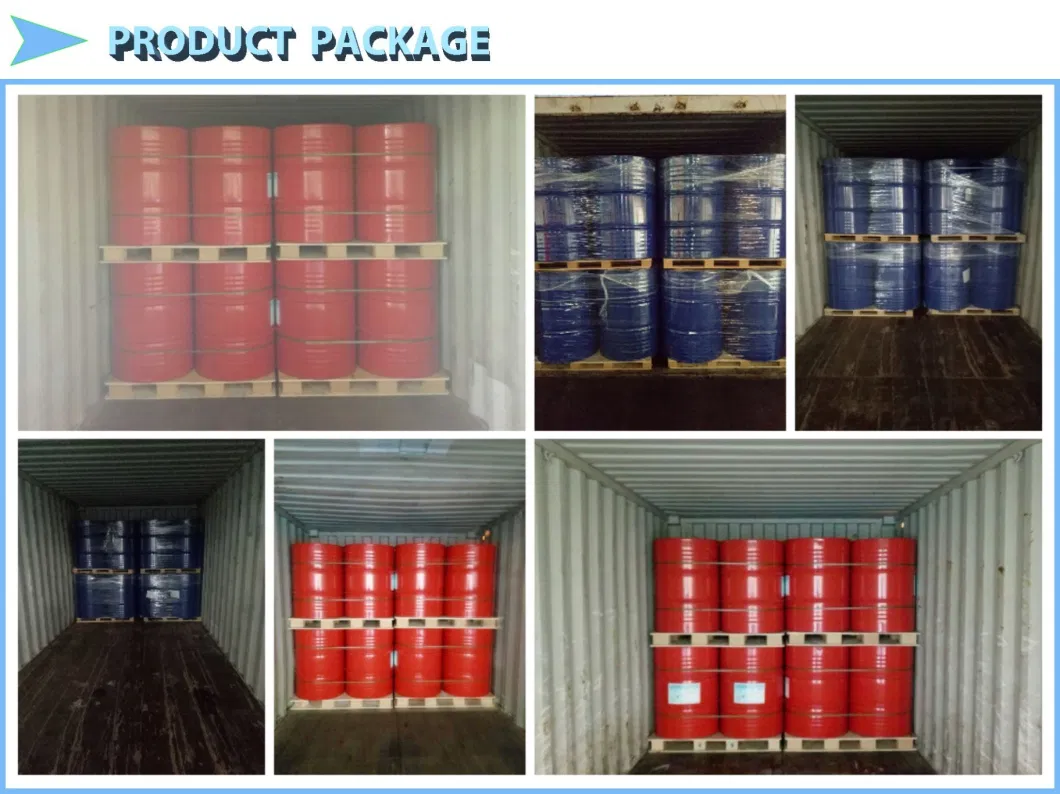

| Transport Package | Steel Drum/IBC Drum/Tank |

| Specification | pure |

| Trademark | G-TECH@ |

| Origin | China |

| HS Code | 390931 |

| Production Capacity | 30000mt/Year |

Packaging & Delivery

Package Size 60.00cm * 60.00cm * 102.00cm Package Gross Weight 218.000kgProduct Description

BLEND POLYOL LY7105LY-7105 is a special polyol formulation designed and developed for the manufacture of sandwich panels in continuous processes. Pen tane or 141b can be used as blowing agent.

It is used in combination with PMDI- ISO7105

In the sandwich panels the rigid polyurethane foam is self-extinguishing B2 accordance to DIN 4102 fire test requirements.

It is recommended to be used for the production of panels with thickness between 30 and 150 mm

TECHNİCAL QUALITY CONDITIONS

| Acid number (DIN 2114) | Max. 1 mg KOH/g |

| Hydroxy number (ASTM 4274-05) | 370±20 mg KOH/g |

| Water content (ASTM 4672-00) | Max. 2 % |

| Viscosity (ASTM 4878-98) | 1800-2100Cps |

| Density (DIN51757) | 1,15-1,20 g/cm3 |

REACTIVITY OF THE REACTION SYSTEM

| Mixing ratio | ( Poly/PMDI/DMCHA) |

| Cream time | / |

| Gel time | / |

| End of rise | / |

| Tack free time | / |

| Free rise density | 28 kg/m3 |

| (All tests are performed at 21 °C. Cream and rise times include a 10 secondstirring time.) | |

HANDLING AND STORAGE

Be careful when working with system, avoid contact with water, do not eat, drink orsmoke during work. Avoid contact with skin, eyes and inhalation of vapours.

LY-7105 is a stable material which can be stored in tanks made from conventional materials used for these applications. Storage temperatures should be kept below 40 °C and above 20 °C to ensure the integrity of the material. It is also recommended that storage vessels and process tanks be blanketed with dry air or nitrogen to prevent uptake of atmosphericmoisture.

The information herein is believed to be correct and is given in good faith, but no warranty, expressed or implied, is made with respect to the product described or its use. As the use of this product is beyond our control, the user must accept responsibility for its suitability for any particular application. No statement may be construed as permission or recommendation for any use that would infringe on any law, ordinance or patent.